Rehabilitation & Upgradation of

Kondli 45 MGD STP

using Euroteck-IFAS

Background

The Kondli STP (45 MGD / 204.3 MLD) was commissioned in 2013 based on Activated Sludge Process (ASP) technology. The plant required rehabilitation and upgradation to meet the latest CPCB/DPCC discharge norms — including biological nutrient removal and improved disinfection — without major civil expansion.

Design / Inlet Characteristics

Existing design parameters at the time of assessment:

| Parameter | Value |

|---|---|

| pH | 7.5 – 8.0 |

| Total Suspended Solids | 30 mg/L |

| BOD (20°C) | 20 mg/L |

| Oil & Grease | Nil |

| Digested Sludge Solid Concentration | 20% |

New discharge standards targeted after retrofit (examples):

| Parameter | Influent | Treated (Norm) |

|---|---|---|

| Flow | 45 MGD | 45 MGD |

| BOD₅ | 250 mg/L | ≤ 10 mg/L |

| COD | 500 mg/L | ≤ 50 mg/L |

| TSS | 450 mg/L | ≤ 10 mg/L |

| Coliform | 1.2 × 10⁶ MPN/100 mL | 100 MPN/100 mL |

| NH₄-N | 36 mg/L | ≤ 5 mg/L |

| TP as P | 8 mg/L | ≤ 1 mg/L |

Challenges

- No existing biological nitrogen or phosphorus removal provision.

- Limited space for new civil structures.

- Inadequate TSS removal and sludge management affecting biogas potential.

- Old aeration systems insufficient for nitrification demands.

- Strict timeline to upgrade without compromising outlet quality.

Proposed Solution — Euroclean IFAS (Euroteck™)

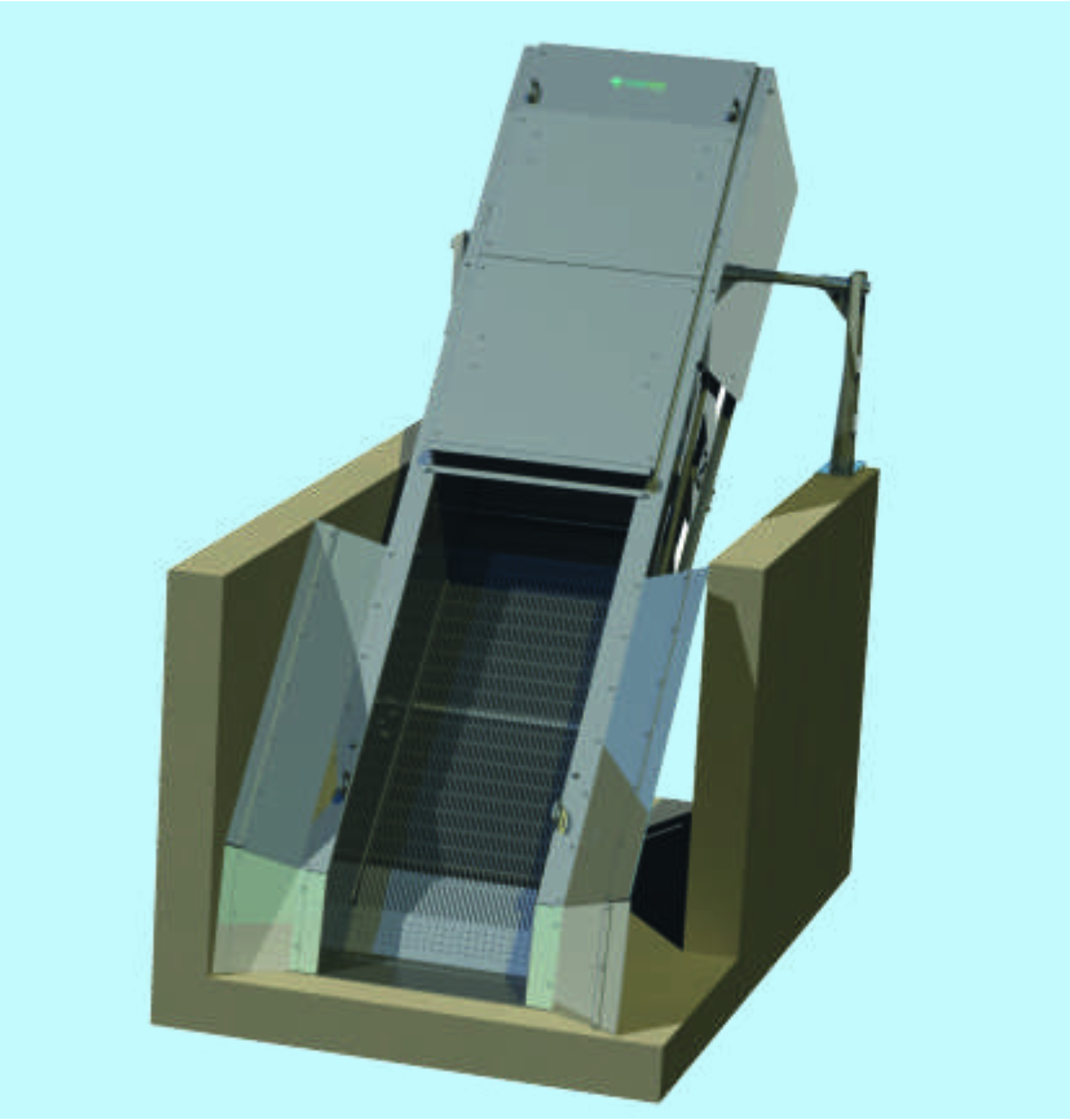

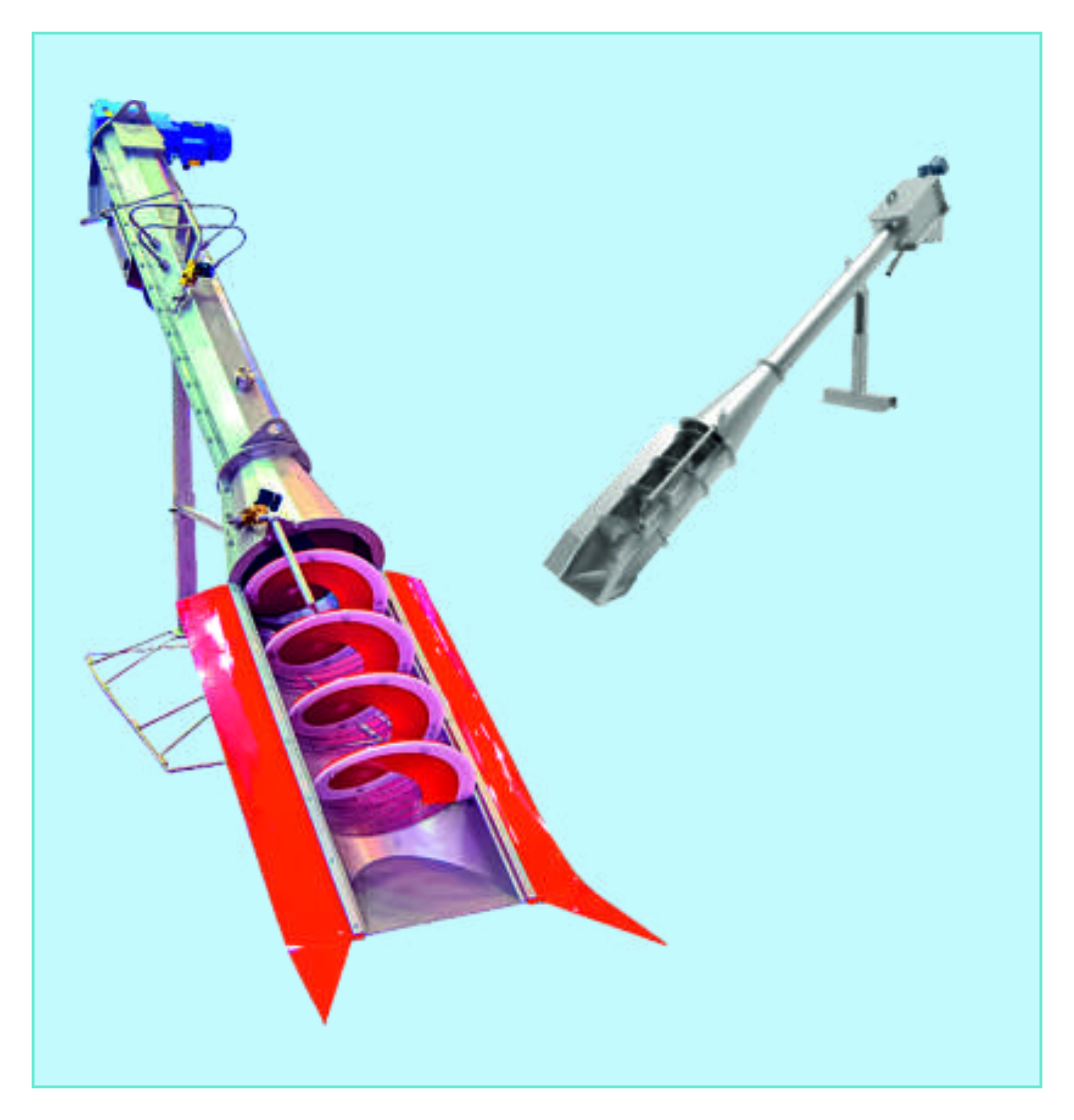

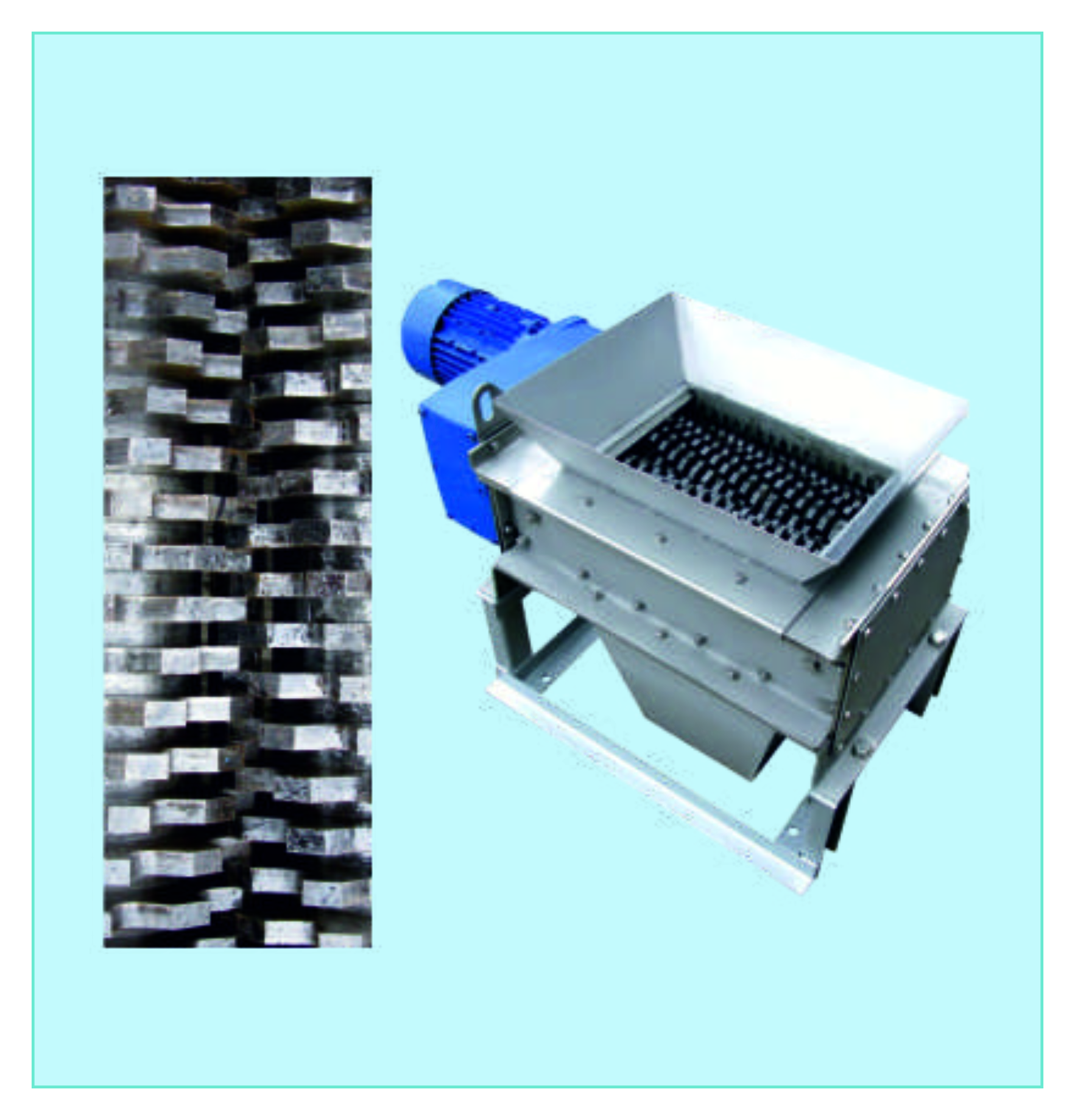

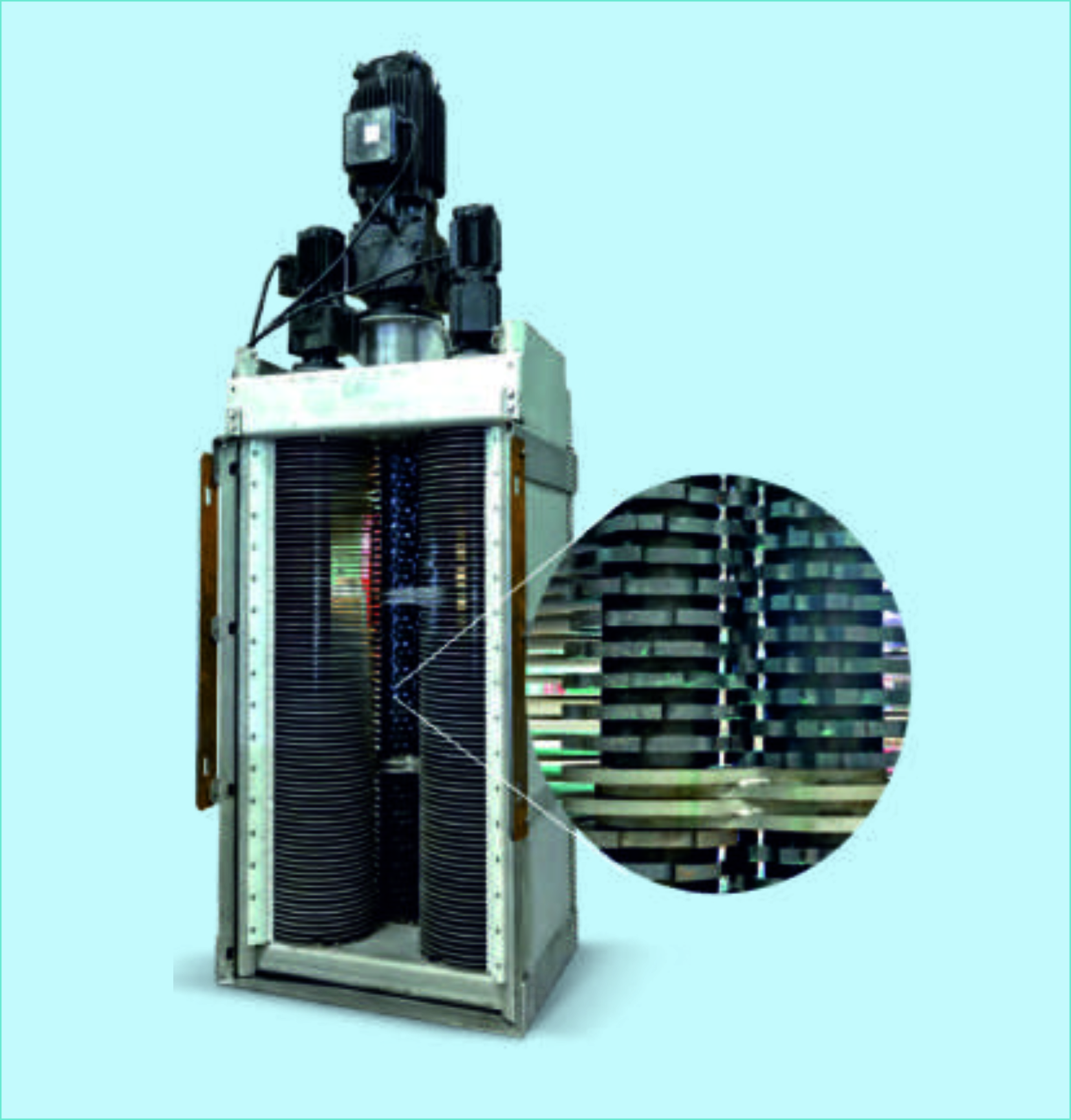

EuroFix™ retrofit (IFAS-A₂O) was selected for quick installation within existing tanks. The solution provided improved nitrification, phosphorus removal, enhanced TSS capture, and energy-efficient aeration — all while keeping the existing footprint.

Key features

- No additional land required; compatible with existing CAS tanks.

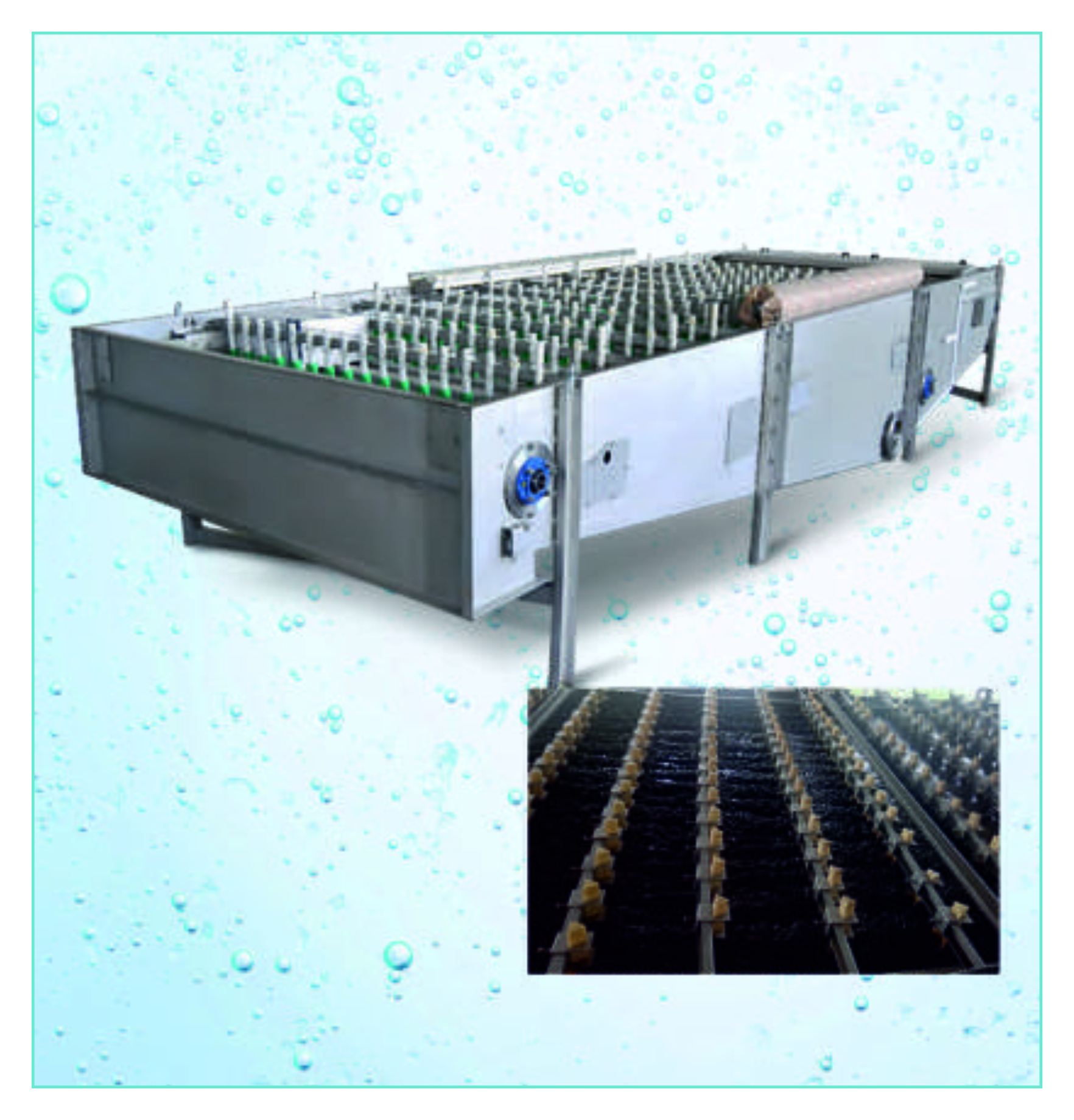

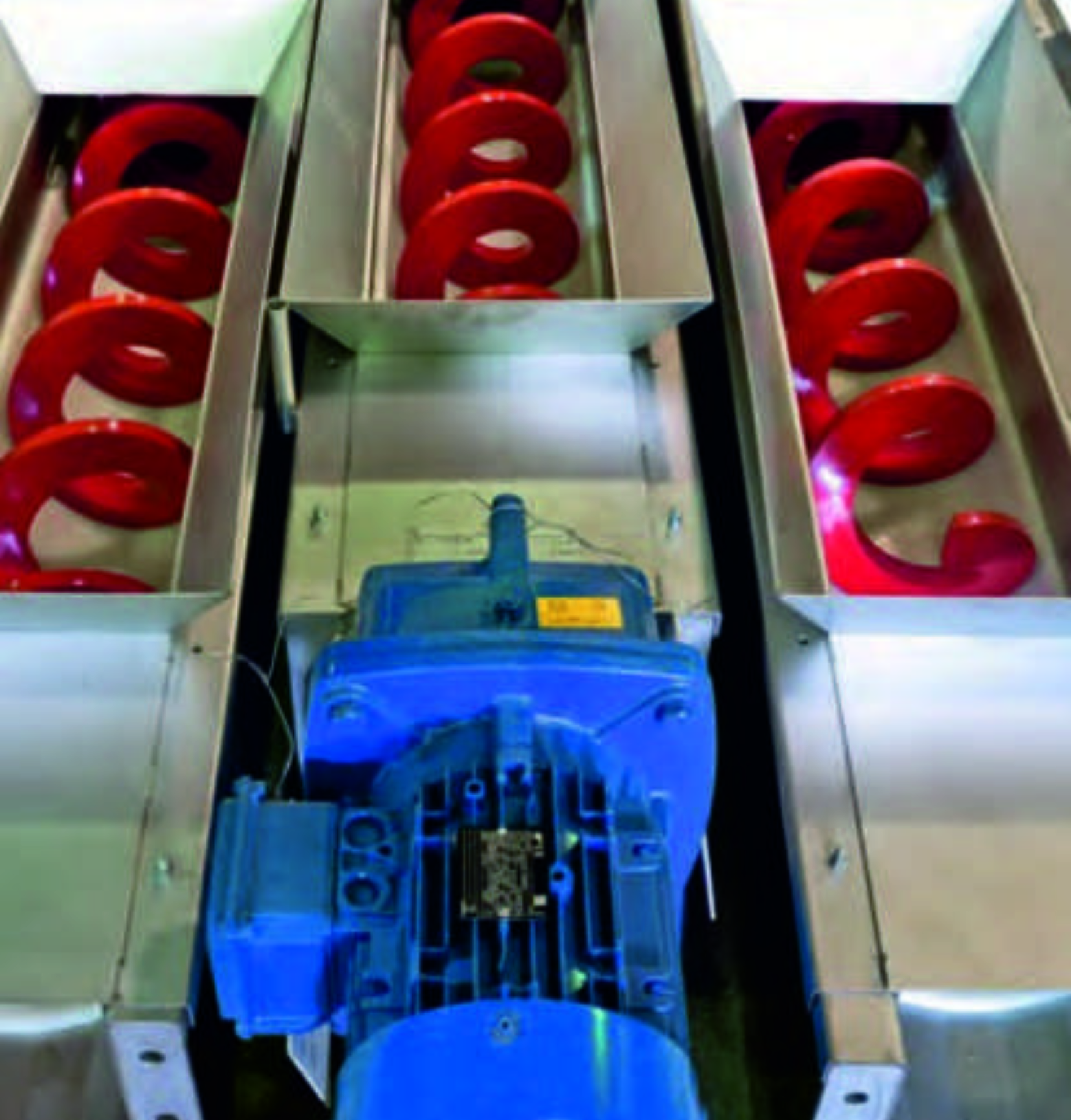

- Euroclean IFAS media modules fitted on stainless frames inside tanks.

- New energy-efficient aeration & DO/NH₄ sensors with OCEMS for real-time control.

- Clarifier modifications and tertiary filtration to achieve TSS < 10 ppm.

- Improved sludge dewatering and enhanced biogas generation.

Design Approach & KPI Achievement

Existing four parallel aeration tanks were retrofitted with anaerobic and anoxic zones (created within the tanks) using IFAS modules and new aeration systems, enabling higher MLSS (5,000–8,000 mg/L) and higher SRT for enhanced nutrient removal.

| Performance Parameter | Before Retrofit | After Euroclean™ Retrofit |

|---|---|---|

| Flow treated (m³/day) | 204,570 | 204,570 |

| BOD₅ removal (%) | 80% | >98% |

| NH₄-N removal (%) | 40% | >98% |

| TP removal (%) | <40% | >80% |

| Effluent BOD₅ (mg/L) | 30–50 | <10 |

| Effluent NH₄-N (mg/L) | >15 | <5 |

| Sludge settleability (SVI) | 180 | 120 |

Result: The plant consistently met effluent standards including during peak loads, improving stability and reducing energy per unit of treated volume.

Cost & Benefit Snapshot

| Category | Conventional Expansion | EuroFix™ Retrofit |

|---|---|---|

| Capital cost | 100% baseline | ~45% of new tank construction |

| Construction time | 12–18 months | 4–6 months |

| Land requirement | +40% | 0% (existing footprint) |

| Gas generation revenue | No improvement | Improved quantity |

Payback period: < 3 years through avoided civil works and operational gains.

ESG & Conclusion

Environmental: lower carbon footprint, improved water quality, efficient resource use, potential carbon credits.

Social: improved community health, jobs, minimal disruption during retrofit.

Governance: better compliance, transparency, and fiscal responsibility.

The Euroteck™ retrofit increased effective treatment capacity, improved effluent quality to meet regulatory standards, and extended the useful life of existing infrastructure — demonstrating a sustainable, space-efficient solution for underperforming STPs.